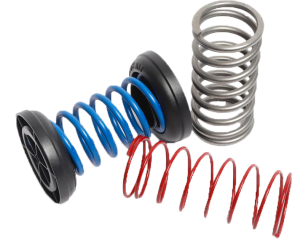

Wireform/Torsion Springs

Torsion Spring Manufacturer

Pa-Ted is an experienced torsion spring manufacturer offering a variety of options, including:

- Wire Sizes From .010″ (.25mm) – .187″ (4.80mm)

- Round, Square and Rectangular Torsion Spring Shapes

- Custom Body Diameter, Length and Pitch

- Single or Double Bodied

Thanks to cutting-edge spring manufacturing techniques, we can hold incredibly close tolerances on all torsion springs. Our torsion designs are ideal for any number of applications from medical to construction.

If you’re searching for a custom spring manufacturing partner,

call Pa-Ted today at (860) 582-6368 to speak with one of our project managers.

Skip to content

Skip to content